Other Products -

Flex-Heat®

Hydronic Comfort System Boiler

When an application requires multiple boilers to provide sufficient capacity and some required redundancy, the Flex-Heat® Comfort System is an ideal choice! Utilizing Series GM™ gas-fired atmospheric boilers, the Flex-Heat system – with inputs of 429MBH to 3,990MBH and beyond (consult factory for larger requirements) – can meet a range of system requirements. The system uses less controls and piping than is used in other systems. The ability to use multiple boilers allows for maintenance of the individual boilers without shutting the entire system down, as would be necessary with a single boiler. In addition, firing multiple smaller boilers is much more efficient than the use of a single larger boiler, especially when only a portion of the capacity is required. The Flex-Heat System is an efficient, service-friendly and dependable system designed to provide years of superior performance.

Product Details:

Type: Semi-Commercial/Commercial

Construction: Cast Iron

Fuel: Gas-Fired (Natural or LP)

Input: 429 to 3,990 MBH

Output: 364 to 3,200 MBH

Venting: Natural Draft

Trim: Water

Ignition: Standing Pilot or Intermittent

![]()

![]()

| System Number | Module Quantity & Size | Input (MBH) | Gross Output (MBH) | Gross Output (H.P.) | Net Output (MBH) | Combustion Efficiency |

|---|---|---|---|---|---|---|

| FH-429 | 2-5 | 429 | 364 | 10.9 | 316 | 82% |

| FH-482 | 1-5, 1-6 | 482 | 408 | 12.2 | 355 | 82% |

| FH-536 | 2-6 | 536 | 452 | 13.5 | 394 | 82% |

| FH-610 | 1-6, 1-7 | 610 | 501 | 15.0 | 436 | 82% |

| FH-684 | 2-7 | 684 | 550 | 16.4 | 478 | 82% |

| FH-741 | 1-7, 1-8 | 741 | 595 | 17.8 | 517 | 82% |

| FH-798 | 2-8 | 798 | 640 | 19.1 | 556 | 82% |

| FH-804 | 3-6 | 804 | 678 | 20.3 | 591 | 82% |

| FH-878 | 2-6, 1-7 | 878 | 727 | 21.7 | 633 | 82% |

| FH-952 | 1-6, 2-7 | 952 | 776 | 23.2 | 675 | 82% |

| FH-1026 | 3-7 | 1026 | 825 | 24.6 | 717 | 82% |

| FH-1140 | 1-7, 2-8 | 1140 | 915 | 27.3 | 795 | 82% |

| FH-1197 | 3-8 | 1197 | 960 | 28.7 | 834 | 82% |

| FH-1220 | 2-6, 2-7 | 1220 | 1002 | 29.9 | 872 | 82% |

| FH-1368 | 4-7 | 1368 | 1100 | 32.9 | 956 | 82% |

| FH-1482 | 2-7, 2-8 | 1482 | 1190 | 35.6 | 1034 | 82% |

| FH-1539 | 1-7, 3-8 | 1539 | 1235 | 36.9 | 1073 | 82% |

| FH-1596 | 4-8 | 1596 | 1280 | 38.2 | 1112 | 82% |

| FH-1710 | 5-7 | 1710 | 1375 | 41.1 | 1195 | 82% |

| FH-1824 | 3-7, 2-8 | 1824 | 1465 | 43.8 | 1273 | 82% |

| FH-1881 | 2-7, 3-8 | 1881 | 1510 | 45.1 | 1312 | 82% |

| FH-1938 | 1-7, 4-8 | 1938 | 1555 | 46.5 | 1351 | 82% |

| FH-1995 | 5-8 | 1995 | 1600 | 47.8 | 1390 | 82% |

| FH-2052 | 6-7 | 2052 | 1650 | 49.3 | 1434 | 82% |

| FH-2166 | 4-7, 2-8 | 2166 | 1740 | 52.0 | 1512 | 82% |

| FH-2280 | 2-7, 4-8 | 2280 | 1830 | 54.7 | 1590 | 82% |

| FH-2394 | 6-8 | 2394 | 1920 | 57.4 | 1668 | 82% |

| FH-2508 | 5-7, 2-8 | 2508 | 2015 | 60.2 | 1751 | 82% |

| FH-2622 | 3-7, 4-8 | 2622 | 2105 | 62.9 | 1829 | 82% |

| FH-2736 | 1-7, 6-8 | 2736 | 2195 | 65.6 | 1907 | 82% |

| FH-2793 | 7-8 | 2793 | 2240 | 66.9 | 1946 | 82% |

| FH-2850 | 6-7, 2-8 | 2850 | 2290 | 68.4 | 1990 | 82% |

| FH-2964 | 4-7, 4-8 | 2964 | 2380 | 71.1 | 2068 | 82% |

| FH-3021 | 3-7, 5-8 | 3021 | 2425 | 72.4 | 2107 | 82% |

| FH-3078 | 2-7, 6-8 | 3078 | 2470 | 73.8 | 2146 | 82% |

| FH-3192 | 8-8 | 3192 | 2560 | 76.5 | 2224 | 82% |

| FH-3306 | 5-7, 4-8 | 3306 | 2655 | 79.3 | 2307 | 82% |

| FH-3363 | 4-7, 5-8 | 3363 | 2700 | 80.7 | 2346 | 82% |

| FH-3420 | 3-7, 6-8 | 3420 | 2745 | 82.0 | 2385 | 82% |

| FH-3534 | 1-7, 8-8 | 3534 | 2835 | 84.7 | 2463 | 82% |

| FH-3591 | 9-8 | 3591 | 2880 | 86.0 | 2502 | 82% |

| FH-3648 | 6-7, 4-8 | 3648 | 2930 | 87.5 | 2546 | 82% |

| FH-3762 | 4-7, 6-8 | 3762 | 3020 | 90.2 | 2624 | 82% |

| FH-3876 | 2-7, 8-8 | 3876 | 3110 | 92.9 | 2702 | 82% |

| FH-3990 | 10-8 | 3990 | 3200 | 95.6 | 2780 | 82% |

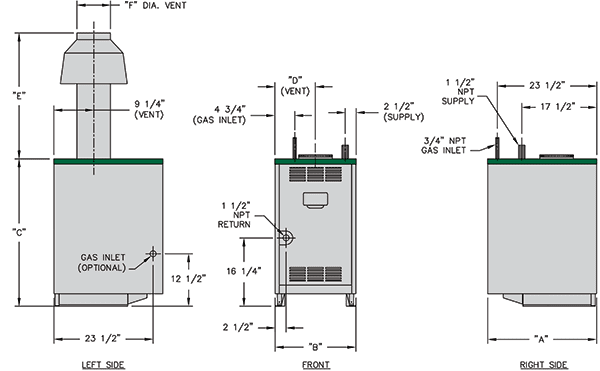

Series GM™ Boiler Dimensions

| Boiler Model Number | Jacket Depth “A” |

Jacket Width “B” |

Jacket Height “C” |

Left of Jkt. to C/L of Vent “D” |

Top of Jkt. to Vent Connector “E” |

Vent Size “F” Dia. |

||

|---|---|---|---|---|---|---|---|---|

| USA, Nat. Gas | Canada or LP | |||||||

| GM–e-05 | 25-3/4″ | 19-1/4″ | 35-1/4″ | 9-3/4″ | 29″ | 7″ | 8″ | |

| GM-e-06 | 25-3/4″ | 22-3/4″ | 35-1/4″ | 11-1/2″ | 30″ | 8″ | 9″ | |

| GM-07 | 25-3/4″ | 26-1/4″ | 35-1/4″ | 13-1/4″ | 31″ | 9″ | 10″ | |

| GM-08 | 25-3/4″ | 29-3/4″ | 35-1/4″ | 15″ | 31″ | 9″ | 10″ | |